Workshop - Project Development Support

For large-scale developments such as those in the marine renewables sector, a holistic approach is required in order to address numerous criteria and constraints.

NEOPOLIA is an industry cluster with complementary skills and expertise. This allows it to operate as a one-stop shop and to provide a multidisciplinary approach right from the early beginnings of a project up to the commissioning of infrastructure. We can provide input across the whole project lifecycle or just in specific areas as required by the project coordinator.

Input areas across the strategic timeline include:

- Siting assessments: seabed surveys and metocean data, geophysical and environmental studies

- Technical pre-project phase: foundations and devices, installation engineering

- Grid connections for offshore infrastructure: Offshore and onshore cable routing

- Regulatory context: Permitting, impact studies, authorisation requests

- Social context: project acceptability

- Economic context: development of an industrial sector, strategic planning of industrial and port infrastructure

NEOPOLIA’s key strength lies its ability to offer comprehensive, integrated solutions:

- A one-stop shop with all-round technical expertise

- Drafting of complex specifications

- Strategic & technical due diligence reviews

Workshop - Offshore Installation Support

Neopolia is a one stop shop for a comprehensive offering on installation support dedicated to Marine Renewables & Offshore Wind industry.

Simple, flexible & effective installation support offer based on extensive experience brought in by industry players partnering up for this solution. Sole interface for a comprehensive solution, integrating engineering, logistics and operations support.

Three themes are defined here below, the list of proposed activities is not exhaustive.

Installation engineering support:

- Appropriate crane selection and development of lifting plans, detailed lifting analyses

- Cargo structural analysis for maritime operations and sea voyages

- Route strength analysis

- Analysis and design of marine operations

- Operation support and maintenance planning

- Heavy loads maneuvers simulations

- Marine Operations planning and design

- Weather and sea conditions studies

Fabrication support:

- Installation aids design and fabrication

- Onshore pre-assembly of components (including shifting, lifting, assembling, coating and cabling operations)

- Pre-commissioning of equipment prior to offshore installation

- Inspection of equipment prior to offshore installation

Logistic hub creation and required quay reinforcement for operations:

- Quay reinforcement (and preliminary loads analysis)

- Logistic hub definition and construction

Logistics and operations support:

- Site survey (local seabed survey, route survey)

- Project management of harbor activities (including schedule, risks analysis, safety, interface with authorities)

- Consulting services (Marine warranty surveyor and Port Captain)

- Heavy Lift Transport (Very heavy cargoes, RO/RO and FLO/FLO operations, Lifting and Skidding operations, Barge transport)

Commissioning and start-up

- Instrumentation and Mechanical supervision

- Start-up

It is the solution to address:

- Installation engineering

- Follow-up and coordination of onshore and offshore activities

- Harbor hub logistic management

- Transport Engineering and Operations

References

- VALOREM MARINE SOLUTIONS: Service provider and expertise in engineering, construction and O&M of MRE projects.

- NENUPHAR: Onshore assembly works of the Vertiwind prototype, an innovative vertical axis floating offshore wind turbine. Erected in 2014 in Fos-sur-Mer, this 50m large and 40m high prototype is actually the biggest operating vertical axis wind turbine in the world.

- Multiple clients: Full EPC of various wind power plants (representing more than 300 MW), including engineering, civil works, electrical works, WTG heavy lift transportation from factory, WTG harbor handling, WTG erection and assembly, grid connection and commissioning.

- OCTRA: Extensive engineering, consultancy and transport operations engineering services. g, consultancy and transport operations references

- FEED for the MRE sector

- Load out of offshore wind nacelles

- Full turnkey transport and associated engineering for one 6MW offshore wind turbine demo project

- Various offshore wind Transition Pieces transport and associated engineering

- Different effective activities on offshore wind floating foundations

- Lifting or erection tools design and manufacturing

- INNOSEA MRE Engineering / Engineering technical consultancy and support services

- Les Eoliennes en Mer: Pre-FEED Installation Engineering for two 500MW wind farms off the French

- STX Solutions: Weather Downtime Calculation tool.

Workshop - Operation & Maintenance

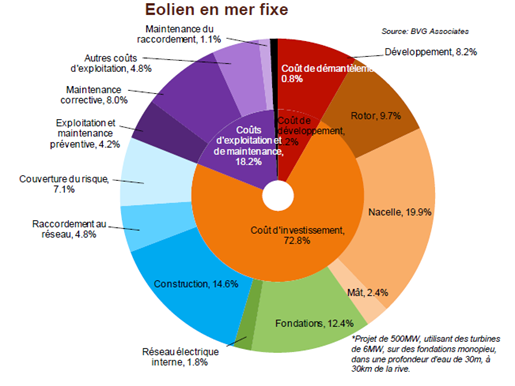

Operation and maintenance (O&M) costs can account for up to 25% of the levelised cost of energy (LCOE) from an offshore wind farm, annual OPEX being considered as about 3 to 5% of  the initial CAPEX for a farm of 500MW. In order to turn offshore wind into a more competitive energy, efforts need to be made on operation and maintenance aspects so that the availability of the farm is optimised, while the operational costs are kept as low as possible.

the initial CAPEX for a farm of 500MW. In order to turn offshore wind into a more competitive energy, efforts need to be made on operation and maintenance aspects so that the availability of the farm is optimised, while the operational costs are kept as low as possible.

In Europe, offshore wind has been providing feedback for decades and such experience has allowed a significant decrease of OPEX associated with a better approach of maintenance at sea. In France, though the sector is still to enter in action, with the first offshore wind farms starting up in 2020, companies have drawn on this experience to upgrade their competencies and be able to face strong competition from international service companies.

Indeed, Neopolia companies have together a strong added value to offer services, tools and facilities that have been adapted to optimally tackle the challenges of offshore wind O&M. The companies taking part in the Neopolia EMR Operation and Maintenance Solution S-EMR04 are able to deliver high quality services responding to all types of needs from stakeholders of offshore wind projects, thanks to their interdisciplinary skills that include:

- metocean data analysis and risk assessment

- offshore site survey (SHM, survey boat, ROV…)

- onshore, harbour and offshore supply chains

- emergency management (air & sea)

- maintenance planning and management.

Competencies can be offered to developers and grid owners as well as turbine, OSS or foundation manufacturers and grid providers, from early engineering of operation and maintenance of the farm to on-site intervention and performance monitoring. Experienced personnel in wind maintenance who are already trained and used to offshore conditions will be able to support ship owners and harbours in providing fast and professional responses for both preventive and corrective maintenance interventions, as well as operational support and follow up both from local bases and remote control centres.

To optimise the costs of O&M while improving the reliability and performance of the farms, the Neopolia EMR O&M Solution always is always keen to develop the best tools and skills through training and innovation for better asset management strategies and offshore logistics concepts.

Workshop - System Health Monitoring

- Asset Management System – Hypervision – SCADA

- Statistical analysis, big-data, decision support, AI

- Forecasting: Weather conditions – Failure prediction – Maintenance scheduling

- Material fatigue – concrete, steel, composites

- Vibratory analysis

- Marine load & chemical behaviour - foundation, machines, cables

- Sensors, data acquisition and processing, communication

Comprehensive Solutions

- Systems architecture consulting

- Design of Monitoring systems, development, installation, commissioning & maintenance

- Asset management for MRE farms

- Help decision for Maintenance optimisation. Detection and prediction of failures

- Operations optimisation for MRE farms

Challenges

- Bottom fixed offshore wind OPEX ~ 20% of total project cost.

- Onshore wind OPEX cost : 45k€ / MW / year

- Offshore wind OPEX cost : 85€k / MW / year

- MRE major challenge : to bring the cost of energy, LCOE, from €100 to €80 / MWh

- Increase the producible 100 hours a year is to lower the LCOE by 3 € / MWh on average

Do the right thing at the right time in Operation and Maintenance

Workshop - Concrete Monitoring in Oceanic Conditions

Monitoring helps operators on- and offshore to avoid unexpected repairs by providing accurate and early indications of structural malfunctioning and behavior in extreme conditions.

Monitoring helps operators on- and offshore to avoid unexpected repairs by providing accurate and early indications of structural malfunctioning and behavior in extreme conditions.

Neopolia is a one-stop shop providing a comprehensive monitoring service for marine concrete structures.

The cluster brings together all its members’ skills and expertise to deliver a distinctive and all-round monitoring solution.

A pioneering solution to help you :

- Boost revenue

- Cut maintenance costs

- Manage the risks

- Understand liability for damage

Engineering & support

- Concept, basic & detail engineering

- Design review & specification design

- Commissioning & start-up

- Operation support & maintenance planning

System integration

- System & sensor installation

- Monitoring software development & implementation

- System test, commissioning & training

Who ? - Who are the potential buyers ?

- Array operatifs

- Maintenance firms

- Constructors

- Demonstrators & prototype projects

Why ? - Why commission this service ?

- Predict faults in order to carry out preventive & repair action

- Plan maintenance operations in line with O&M schedules

- Reduce the cost of any repairs

- Access liability in the event of any incident, & to date the onset of the damage

What ? – It collect information about :

- Early concrete temperature

- Damage

- Structure stress

- Water infiltration

Where ? – This solution mainly applies to :

- Quays

- Monopole steel foundations with grouting junctions

- Jacket foundations

- Floating structures

When ? – Our intervention can involve 3 stages :

- From the design & then project call phase

- During the works : monitoring is directly applied to the reinforcement inside the formwork before concrete is poured

- During the maintenance phase for data monitoring & analysis